Solving the PLM Puzzle with 4G:PLM

Product Lifecycle Management systems are overly complex… but they don’t need to be. If the cure is worse than the ailment most people won’t want it. And that’s the problem with PLM – it is a puzzle. Many companies spend huge budgets on tools and consultants. Once deployed the tools are loathed by users…

- How can you figure out a better way when you’re constrained by the tools?

- How do you get users to use the tool? You’d like them to want to ‘add books to the library’ of product knowledge, but if it is too complex for the casual user, what can you change? The greatest product librarian tools aren’t any good if you don’t have any “books in the library”!

- The overall cost (including solution architects, user’s time, etc.) can soar – isn’t there a better, low cost alternative to ePDM, workgroup PDM, enterprise PLM?

We heard from a client the other day that the PDM system used by many SolidWorks users doesn’t sort the Bill of Materials properly. Each time the BOM is extracted it randomizes the order of the items, thus making it more difficult for the downstream manufacturing partners to sort out what’s changing between revisions of the assembly.

We proposed a simple solution using 4G:PLM coupled with PDM from SolidWorks. The key features are the ability to manage and redline (edit) the bill of materials after it comes from CAD. With 4G:PLM you can make the changes that don’t impact CAD and capture electronic approvals within the PLM system. The BOM sort order, using Find Numbers, are equivalent to the balloon numbers of the assembly drawing. Thereby downstream manufacturers (with access to 4G:PLM or a report from the tool) can quickly realize what’s changing within the BOM revisions.

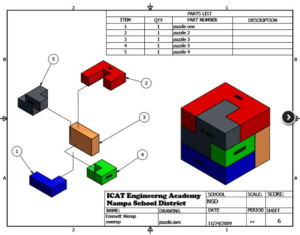

A simple example illustrates this principle.

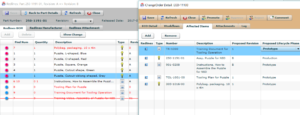

We found a student’s CAD project online and decided to enhance his documentation with 4G:PLM. It took less than 5 minutes to capture the BOM, create a special sub-class of “Puzzle Items” with appropriate semi-intelligent part numbering schema and build the BOM, and then output it to Excel.

We then decided to do a few more thing like enhance the BOM with new items (a tooling plan, and more document items) and release the REV B through an ECO.

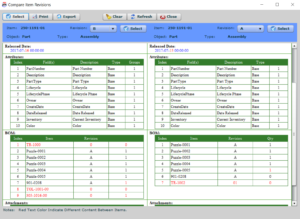

Finally, we were able to run the BOM comparison report in 4G:PLM between Rev A and REV B to visualize what’s changed between these two releases.

Have we solved the PLM puzzle? Probably not completely, but within a few minutes you can see how easy it was to create enhanced documentation for the CAD designer downstream. To be able to do this kind of work with a low cost solution (around $50/user) is incredible. That’s why we call our tool a fourth generation PLM solution for small to medium sized businesses. Watch this full overview of 4G:PLM and you’ll see how easy it is to create parts, export the BOMs and make revisions to your assemblies without a complex PDM/PLM tool.