What is the Affordable PLM Act?

You’ve all heard of the Affordable Care Act – at least those of you following modern politics in the USA. With our newly elected president there’s a lot of hoopin’ and hollerin’ going on about this legislation across the country. Perhaps it will be repealed, and/or replaced, but it will take a real act of congress to move on this initiative.

Strange how this closely aligns with starting a new company-wide initiative for PLM (Product Lifecycle Management). To get a new system into the company, or to ‘repeal’ the current system, you’ll need to move a mountain of politics and get all parties to ‘buy in’ to the change. Do not despair – there is now HOPE with 4G:PLM! The three keys to making this work:

- Education – get everyone trained on what’s really going on today, how it can be better and how you can eventually get 100% coverage on your systems and processes.

- Affordability – if the Return on Investment (ROI) can be measured in weeks versus years (or in some cases decades for legacy PLM systems) then you’ll be able to kick-off the pilot programs and roll-out a solution which can solve real problems for pennies on the dollar.

- Simplicity! Don’t try to boil the ocean when it comes to building and implementing a new initiative. Focus on the essentials and deliver in record time.

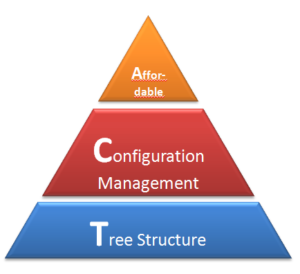

In the spirit of simplicity, why don’t we revert to a few images to explain the Affordable PLM ACT.

A stands for Affordability. At the top of the pyramid you’ll find this is the keystone for this initiative, even when budgets are tight. You can afford to try out a comprehensive PLM solution for one user at $50/month. That’s less than $1.65 a day -probably the kind of money wasted just walking to the water cooler. If you can manage your product configurations better and build the ‘right BOM’ in a low cost PLM versus via spreadsheet, then affordability is your friend. You can kick off a new method of doing business.

C stands for Configuration Management. PLM systems bank on proper configuration management. It is the main reason for putting a system in in the first place. If you think you can manage a Bill of Materials with many users, and many parts and many suppliers all working on the same spreadsheet, then more power to you. This is not simple and a real PLM tool needs to track everything – who did what to what, when, and what’s the current revision.

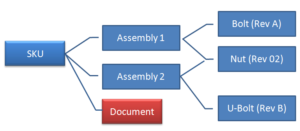

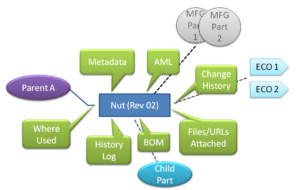

T stands for Tree Structure. An indented Bill of Materials (BOM) is not flat like a spreadsheet but it forms a tree structure with the roots being the “SKU” or sale able item and/or some companies call this the ‘Catalog item’ or TLA (Top Level Assy). Each branch goes to a child component and each child can have one or many grandchildren parts. Where things get complicated is when you need to track various data elements about each child and the relationships and what’s current versus outdated and all of the change history… and so forth. This illustrates all of the potential directions one can go when

researching a single component. This nut is used on two parents (Assembly 1 and Assembly 2 above), it contains ‘meta data’ or searchable information/ data about the data, as well as AML (Approved Manufacturers List), links to what changes happened when, specs, data sheets, attached CAD files, child components (if any), perhaps relationships to assembly instructions, etc. There are a lot of things going on with this “simple” nut.

Conclusion

Getting a new PLM system into your company may be a tough nut to crack, but if you can even try out 4G:PLM you’ll notice how comprehensive it is for a VERY AFFORDABLE price tag. It is time for you to ACT. Subscribe to our Youtube channel to see the latest from SolidPartners 4G:PLM. Our vision is to democratize PLM and allow 100% of the users access to affordable health care, er.. enterprise software to keep your products and factory healthy.